What Is an Engine Mount? An In-Depth Guide

Engine Mounts Explained: Everything You Need to Know

Find your tyre

READ THE DIMENSIONS OF TYRES

When you hear the term engine mount, you probably don't think of how important this little component is to your car's maintenance or performance. However, the engine mount plays a substantial role in keeping your vehicle running smoothly, ensuring comfort, stability, and reducing wear on the engine. Whether you are a car enthusiast or just someone who wants to keep your vehicle in good shape, knowing about motor mounts and their function can save you from costly repairs.

In this in-depth guide, we will go over types of engine mounts, why they are important, how they work, and how to replace them. We will also cover common signs of failure of an engine mount, the causes, and the possible consequences of continuing to drive with a damaged motor mount.

What Is an Engine Mount?

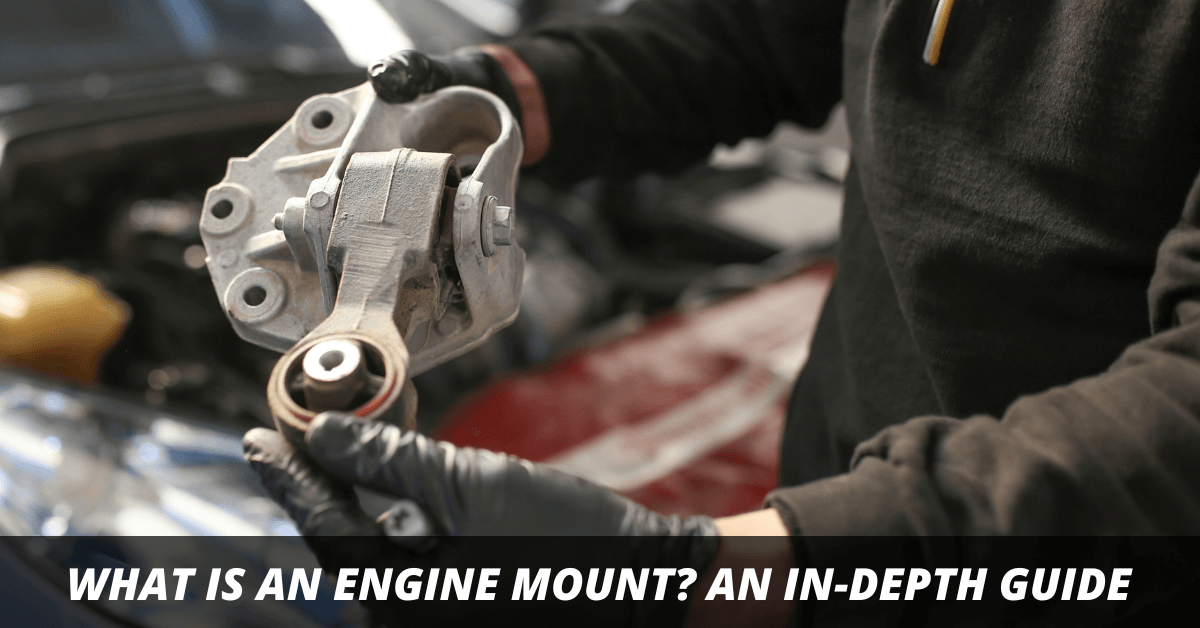

A motor mount (also called an engine mount) is a part that physically mounts the engine to your car's chassis or subframe. Its main function is to hold the engine in position, absorb vibrations that are created by the engine's movement, and stop the engine from moving around too much. Without an engine mount, the engine would make unwanted movements while driving that would cause discomfort, and excessive noise, and could even lead to damage to other very important parts of your car.

The majority of engine mounts contain metal and rubber. The rubber or polyurethane section acts as a cushion, absorbing vibrations, while the metal bracket holds the engine in place, securing it to the vehicle's body. Some high-tech hydraulic engine mounts also have a fluid-filled chamber to further dampen the vibrations for an even smoother ride.

Types of Engine Mounts

You have various kinds of mounts available in the market. They are designed to suit the different types of vehicles, and each mount serves for a different purpose according to the driving conditions. Here are the most common ones:

1. Traditional Rubber Engine Mounts

These are the most commonly used mounts, found in most everyday vehicles. Made from durable rubber, they provide a simple and cost-effective solution for absorbing engine vibrations.

2. Hydraulic Engine Mounts

Hydraulic motor mounts contain a liquid-filled chamber that enhances vibration absorption. These mounts are typically found in higher-end vehicles and are ideal for luxury cars driven in regions like the UAE, where smooth performance is critical. While these mounts are more expensive, they offer superior noise reduction and more advanced vibration dampening.

3. Solid Engine Mounts

Most high-performance vehicles, including race cars, often employ solid engine mounts. Made from solid metal or polyurethane materials, these mounts are designed to provide extreme stability.

4. Active Engine Mounts

Active engine mounts are electronically controlled and change their stiffness in real time to optimize the absorption of vibrations, given the operating conditions of the engine. Usually, these mounts are used in higher-class vehicles, including electric and hybrid ones, in order to provide the greatest level of comfort while driving.

Importance of Engine Mounts

The engine mount serves several key purposes:

- Vibration Reduction: It has a very important role in reducing the vibrations occurring due to the running of the engine. Without the engine mount, the vibrations would directly get transmitted into the cabin of the vehicle, which makes the ride uncomfortable.

- Preventing Engine Misalignment: The motor mount ensures that the engine stays aligned with other vehicle components, such as the transmission, exhaust system, and belts. Misalignment can lead to premature wear and tear of these parts.

- Noise Dampening: The mount helps absorb noise and vibrations from the engine, reducing rattling and clunking noises.

- Engine Stabilization: The mount of the engine assists in keeping the engine in its proper place, thus preventing extra movement that would affect the handling and performance of the vehicle as a whole.

How Does an Engine Mount Work?

The engine mount works by effectively anchoring the engine to the vehicle's chassis or subframe, while at the same time absorbing vibrations generated in the movements of the engine. It acts to dampen the engine by preventing excessive movement as a car accelerates, decelerates, or negotiates uneven terrain.

Hydraulic and active engine mounts can change their damping characteristics to offer a smoother ride. For example, the mount in a high-power vehicle will stiffen as the engine makes more power to reduce vibration and optimize stability. On the contrary, at lower speeds or when the engine is at an idle, the mount softens to absorb more vibrations and noise.

Signs of a Failing Engine Mount

Engine mounts eventually fail over time. Noting the signs of motor mount failure early on can save you from more serious damage and a costlier fix. Some common signs include:

- Increased Vibration: If you feel excessive vibrations or shaking while idling or accelerating, it may be a symptom of a worn engine mount.

- Clunking or Banging Noises: If you hear strange noises when shifting gears, it may be due to the engine moving inside the engine bay.

- Engine Misalignment: If you find that the engine seems to be tilted or misaligned, then it is an obvious indication that the engine mount is damaged.

- Abnormal Engine Movement: When you shift from park to drive or reverse, you may notice the engine moving or shifting more than usual.

- Excessive Engine Movement: If the engine visibly moves or tilts when you accelerate or decelerate, it’s time to replace the motor mount.

Causes of Engine Mount Failure

Several factors can contribute to engine mount failure:

- Heat Exposure: The extreme heat in the UAE can cause rubber mounts to degrade and harden, losing their ability to absorb vibrations.

- Oil Leaks: Leaking engine oil can weaken the rubber material in engine mounts, causing them to fail prematurely.

- Driving Habits: Aggressive driving, sudden acceleration, and hard braking can put excess stress on motor mounts, leading to early wear.

- Age and Wear: As with any car component, engine mounts wear out over time. Most mounts last between 5 to 7 years, depending on the vehicle's usage and environment.

Consequences of Driving with a Damaged Engine Mount

If you continue to drive with a damaged or failing engine mount, the consequences can be severe.

- Increased Vibration and Noise: Excessive vibrations from the engine can lead to a bumpy, uncomfortable ride.

- Damage to Engine Components: A misaligned engine can cause damage to other engine components, such as belts, hoses, or the transmission system.

- Stress on Other Mounts: The failure of one engine mount increases the stress on the other mounts, which causes them to fail sooner than they should.

- Potential Engine Damage: Excessive movement of the engine can cause the engine itself to be damaged. Repairs or even replacement of the engine may be needed in such cases.

Because of these reasons, replacing a motor mount as soon as it is damaged will prevent further problems.

How to Inspect an Engine Mount?

Checking your engine mount from time to time is crucial to help you catch possible issues before it worsens. Here's how to check:

- Visual Inspection: Look for visible cracks, leaks, or deformations of the mount. If you notice oil leaks or visible damage, it is time to replace the mount.

- Engine Movement Test: Start the engine and watch whether the engine tilts or moves excessively. Shifting of the engine, when accelerating or decelerating, may be an indication of a failing mount.

- Professional Inspection: For better accuracy, it would be good to have your engine mounts checked by a professional mechanic. Come visit TyrePlus UAE for a thorough checkup.

Replacing an Engine Mount: DIY vs. Professional Help

While it's doable, engine mount replacements are labor-intensive and call for lots of mechanical aptitude; DIY Engine Mount Replacement done wrong will be dangerous. For that reason, replacing the mounts should be sought from experts.

Professional mechanics, such as TyrePlus, can replace engine mounts efficiently, ensuring the task is taken care of effectively the first time.

Also Read: DIY or Professional Car Battery Replacement: Which is Right for You

Engine Mount Replacement Cost in UAE

Engine mount replacement costs depend on both the mount type and the car.

- Standard Rubber Mount: AED 500 – AED 1,000

- Hydraulic/Active Mount: AED 1,200 – AED 1,800

- High-Performance or Custom Mount: AED 1,800 – AED 2,500

For more information call or book an appointment online to get an accurate price quote for engine mount replacement. Visit your nearest TyrePlus service center to grab special Offers.

Tips to Follow to Ensure Engine Mount Life Span

Some tips for making sure the engine mount stays in shape include:

- Inspect Regularly: Have a regular inspection of your motor mounts; look for signs of cracking or leaking.

- Leaking Fluids: Oil and coolant leaks erode the engine mounts.

- Drive Smoothly: Avoid sudden starts and stops to reduce the unnecessary load on the mounts.

- Use OEM Parts: Always use high-quality or OEM replacement mounts to maintain optimum performance and durability.

Frequently Asked Questions

How long do engine mounts last?

Can bad engine mounts affect acceleration?

Is it safe to drive with a bad motor mount?

How much does it cost to replace an engine mount?

How long can you drive with broken motor mounts?

Can engine mounts cause vibration?